Maximizing Bio-Renewable Energy from Wet Wastes

(M-BREWW)

The main pollutant in wastewater is organic solids. These solids are measured as chemical oxygen demand (COD) or the amount of oxygen required to decompose the organics available in the wastewater. Wastewater contains a high amount of COD. Releasing wastewater directly to a stream, river, or lake, depletes the local area of all the available dissolved oxygen that aquatic wildlife need for survival. Thus, wastewater is sent to treatment facilities to remove COD and other potential health hazards.

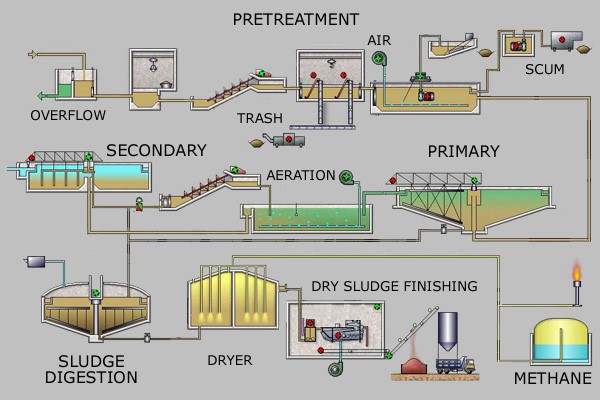

Traditional wastewater treatment processes consist of two treatment streams: solids and liquid. At the start of the treatment process, primary settling tanks separate the liquid from heavier solids via sedimentation. Then the liquid passes through activated sludge treatment, which removes organics aerobically and releases carbon dioxide. The liquid passes through secondary settling tank after the activated sludge process, to remove remaining solids. The liquid will in some cases be further polished by filtration and disinfection prior to being released to an adjacent stream or lake. The solids are collected from the settling tanks and go to an anaerobic digestion tank. Subsequently, the solids are dewatered and then either landfilled or applied to agricultural lands.

Flow diagram of traditional wastewater treatment plant processing (artwork by Leonard G.).

This conventional treatment process generally has a significant energy demand. In particular, the activated sludge step requires a large energy input for aeration to maintain the optimal dissolved oxygen for the aerobic bacteria. Additionally, this process creates carbon dioxide that escapes to the atmosphere. In contrast, wastewater solids can be used to create bioenergy products. These bioenergy productscan in turn used to create an energy neutral treatment facility or sold for revenue.

Past research has shown that wastewater treatment plants can increase bioenergy yields significantly by feeding wastewater directly into the anaerobic digestion process before the activated sludge (aerobic process). However, this approach generally requires the use of a membrane to separate the solids and liquid retention time. But, most current membrane systems have a large energy input that is needed to force the water through the membrane. In this method, the anaerobic process still doesn’t remove ammonia, so it would still need to be removed by including an aerobic step.

ISTC researcher Lance Schideman, and colleagues from the University of Illinois Urbana-Champaign, Ohio University, and the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory have developed a new process called distributed low-energy wastewater treatment (D-LEWT). The D-LEWT system converts wastewater organic solids and ammonia into two harvestable fuels for biopower production (specifically methane and hydrogen gases).

The D-LEWT system combines a new type of anaerobic membrane bioreactor with clinoptilolite ion exchange and ammonia electrolysis steps. The membrane bioreactor naturally produces methane when the anaerobic bacteria “eat” the organic solids. In the ion exchange step, clinoptilolite is a naturally occurring mineral that captures and concentrates ammonia. Finally, the ammonia electrolysis step breaks apart the ammonia into nitrogen and hydrogen gases. This process is similar to how water can be split into oxygen and hydrogen gases. Both the methane and the hydrogen gases can be captured for energy use.

The team’s previous work on the D-LEWT system consisted of bench- and pilot-scale testing of the components of the D-LEWT system. The goal of this new DOE project is to combine all the components of the D-LEWT system into a fully functioning pilot-scale unit. By combining these three parts and making the improvements to the system, this project could increase energy production at a wastewater treatment plant by up to ten times that of previous production. In addition, the D-LEWT system could replace nearly all of the traditional wastewater treatment process.